EAGLE EYE ENGINEERS AND MANUFACTURES THE MOST ACCURATE & CONSISTENT PRECISION MATCH AMMUNITION FOR LONG RANGE SHOOTING

Eagle Eye Precision Match Ammunition

Eagle Eye Ammunition engineers and manufactures long range high precision high kinetic effects ammunition for military, competition and hunting markets. Our cartridges are used by world class competition shooters, the US Army Marksmanship Unit and the United States Special Operations Command. Competitors consistently win some of the most prestigious competitions including the Precision Rifle Series Golden Bullet, USASOC International Sniper Competition and the North American Sniper Team Invitational (NASTI) with our ammunition. We are a group of Ph.D. statisticians, research scientists, engineers and long range shooting aficionados. We founded Eagle Eye to address two primary flaws in traditional off the shelf ammunition. First, the manufacturing processes and quality control standards of traditional factory ammo is very poor. Secondly, typical factory loadings fail to utilize the entire performance potential of a cartridge and the loadings are not fully optimized for long range precision shooting.

Eagle Eye Ammo Shooters win Lepuold NRL Southern Challenge

Manufacturing Processes & Quality Controls:

In the past precision shooters chose to hand load their own ammunition because they could ensure more consistency on almost every factor (ie. neck tension, powder charges, seating depths etc.) than they could get from any commercial off the shelf ammunition. The reason for this is that major commercial ammunition is still manufactured using the same equipment and methods that have been used prior to World War II. While the ammunition industry struggles to control factors to within a few thousands of an inch (10^-3), other industries such as biotech, electrical and materials are routinely manufacturing commercial products on the nanoscale (billionth or 10^-9). In today's world, isn't it about time the ammunition industry is able to at least offer commercial off the shelf cartridges with hand loaded consistency or better? We think so.

Prior to Eagle Eye some of the projects we were working on were things such as developing invitro diagnostic devices that would measure gene expression levels of a tissue sample to screen for things such as non-small cell lung cancer. We realized that if we applied the automation technologies and process control systems used in things such as medical cancer diagnostic device manufacturing it would possible to manufacture precision ammunition as consistently, if not more consistently, than can be hand loaded.

To manufacture the most accurate and consistent ammunition, we chose to custom design and engineer our production machinery and tooling from a blank sheet of paper. Our specialized loading machinery does not exist anywhere else in the world. We utilize the latest automation technologies, control systems and most importantly human attention to detail to ensure the highest levels of consistency. We engineer and manufacture our tooling and dye sets that that are specifically matched to our individual cartridges for unmatched precision.

Eagle Eye Precision Match cartridges undergo constant testing throughout the manufacturing process. Modern statistical quality control methods have been implemented and are monitored by a Ph.D. statistician. Quality testing begins with extensive inspection to ensure conformity of all incoming raw materials and components before they are used in manufacturing. Advanced uni-variate and multi-variate control charting is used to monitor production in order to proactively prevent out of spec products at any step in manufacturing. Once the cartridges are completed they undergo dimensional screening, each lot is test fired for accuracy, the velocities and trajectory are verified for unrivaled consistency. In addition to automated in-process inspection, every round of Eagle Eye Precision Match ammunition is given a final hand inspection while being hand packaged.

|

|

Eagle Eye Precision Ammunition in Eagle Eye 100 Round Boxes

Maximizing Ballistic Perforance:

There is much more to precision shooting, especially at long ranges, than just small groups on paper at 100 yards. While ½ minute or small groups at 100 yards is never a bad thing, this alone does not guarantee a small group or hits at long ranges. It is important to look at the entire ballistic package. One critical factor is the consistency and standard deviation of the muzzle velocity. The larger the variation in initial muzzle velocity from round to round, the larger the vertical dispersion in the point of impact will be; especially at long range. In traditional factory ammunition, velocity standard deviations of 15-20+ fps and extreme spreads of 60-100fps are not uncommon occurrences. For perspective, such a deviation in a 6.5 Creedmoor could result in over 2 feet difference in vertical point of impact at 1,000 yards! In this instance, even if the shooter did everything perfect, inconsistent muzzle velocities would result in approximately 2.4 minute of angle group size from vertical dispersion alone. Eagle Eye Precision Match Ammunition is engineered to provide more consistent single digit velocity standard deviations in well maintained match rifles. We work to control velocity standard deviations in a number of ways. First, our cases are prepared for loading to obtain the most consistent neck tension from round to round. Secondly, our propellant charges are carefully dosed with the highest precision possible. Finally, we utilize specially developed extruded propellants with burn characteristics specifically matched to our case geometry and the projectile of choice for maximum consistency.

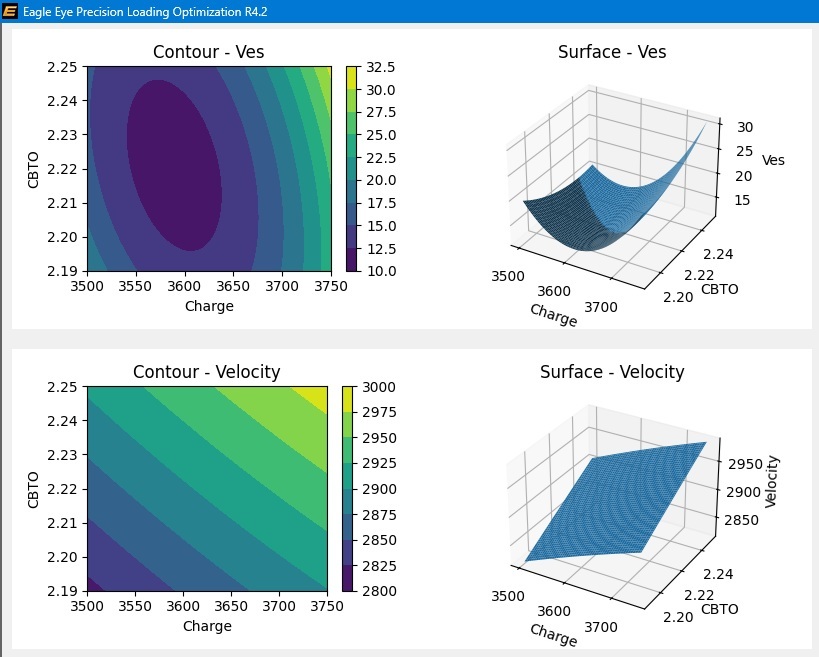

To further aid in optimizing loading specifications of our cartridges, we leveraged our background in statistics, mathematical optimization and computer programming to develop a suite of algorithms and sofware packages for modeling ballistic performance. We utilized carefully designed testing protocols in a range of rifles to collect critical performance data on a variety of loading factors. This testing allows us to build sophisticated mathematical models that descrie how changes in loading parameters will influence ballistic performance characteristics such as accuracy, velocity and velocity standard deviation. From here, we use these models to identify the optimal loading formulation in order to produce the best ammunition possible.

Eagle Eye Precision Today:

Eagle Eye Shooters at Nightforce ELR Competition

As of 2025 we are happy to celebrate our 11th year in business. Eagle Eye Precision Ammunition is for the real shooting aficionado. We are dedicated to offering the most consistent and accurate ammunition available. Our 21st century state of the art ballistic modeling, manufacturing and control processes ensure the tightest manufacturing tolerances and lot to lot uniformity. In addition to shooing small ½ minute or better or groups on paper at 100 yards, our ammunition offers the lowest velocity standard deviations and is loaded to its maximum potential for enhanced kinetic energy and unsurpassed long range precision. Whether you are shooting groups at 100 yards, shooting Extreme Long Range competitions with targets over a mile away, on a military deployment or on the trophy hunt of a lifetime Eagle Eye Precision ammunition is engineered to perform when it matters most.

We thank you for allowing us to be your choice in precision match ammunition,

- The Eagle Eye Precision Ammunition Team